copyright AICHELIN

CHAMBER OVEN WITH CONTROLLED ATMOSPHERE

This type of furnace is widely used in almost all Heat Treatment processes and can also be used in Thermochemical Treatments.

Among the advantages of this model, it is worth highlighting the high flexibility of processes and great accuracy of layer results, metallurgical structures, resistance and hardness. In addition, the chamber furnace with controlled atmosphere also has a technology system integrated with the demands of industry 4.0.

Application processes in Heat Treatment:

Construction Features:

- Built on geometry consecrated by efficiency, with application of intuitive design in the areas of connectivity and interaction;

- Thermal insulation designed respecting the thermal profile parameters of ergonomic cold face, aiming at energy savings, heating efficiency and operational comfort;

- Frame and structure built in appropriate materials for the severity of the application, guaranteeing robustness and longevity to the equipment;

- Heating systems developed according to the process, whether in high efficiency resistive elements, monobloc, dual or recuperative burners;

- Energy efficiency guaranteed by world renowned brands;

- In electrical heating, it has power control by electronic means of high reliability, via solid state or thyristor modules;

- In gas heating, the control systems have approved programmers and safety systems according to NBR 12313;

- Micro processed temperature control system, with ramps and levels, work and safety pyrometry, evaluation and certification of several TUS points;

- Sistema de supervisão, composto por hardware, programação das telas de processos e manutenção dos equipamentos, com armazenamento de dados de produção com identificação de lotes / receitas afins de rastreabilidade.

- It contemplates the Brazilian Occupational Health and Safety Standards with: NR 10, NR 12, NR 17, Preliminary Risk Analysis report, certification reports and effectiveness ART.

Grefortec Maintenance

Benefits

We have a qualified team to handle corrective and preventive maintenance on industrial equipment from our brand and also from other manufacturers. Our professionals are trained and qualified in accordance with the Safety Regulations. We go to your company to carry out maintenance on site.

Of production time is wasted due to lack of maintenance

Of industrial companies use preventive maintenance

It is the Grefortec maintenance satisfaction index

Renovations and Retrofit

Team specialized in general renovations, recovering everything from the structure and plating to the electronic parts. Grefortec also has Know-how for retrofit services, refractory and insulation reforms.

Disponibilidade 24h

Nossa equipe técnica está disponível 24h por dia, com a possibilidade de realizar a manutenção in loco, sem necessidade de deslocamento. Nós vamos até a sua empresa!

Spare Parts

Resistors, radiant tubes, conveyor chains, atmosphere recirculators, baskets, grids and miscellaneous items:

Resistance

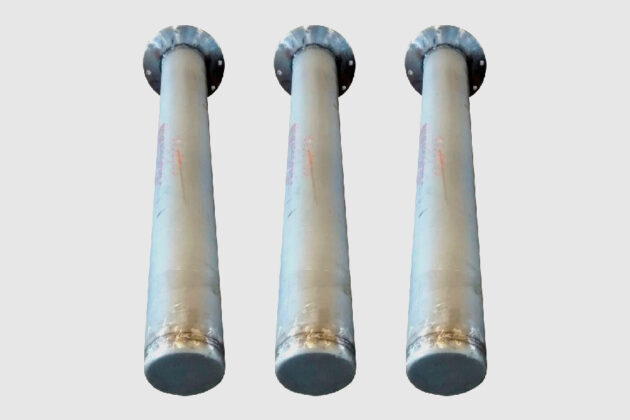

Radiant Tubes

Conveyor-currents

Atmosphere Circulators

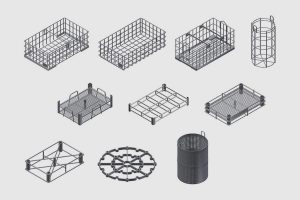

Baskets and Grilles