Nitriding

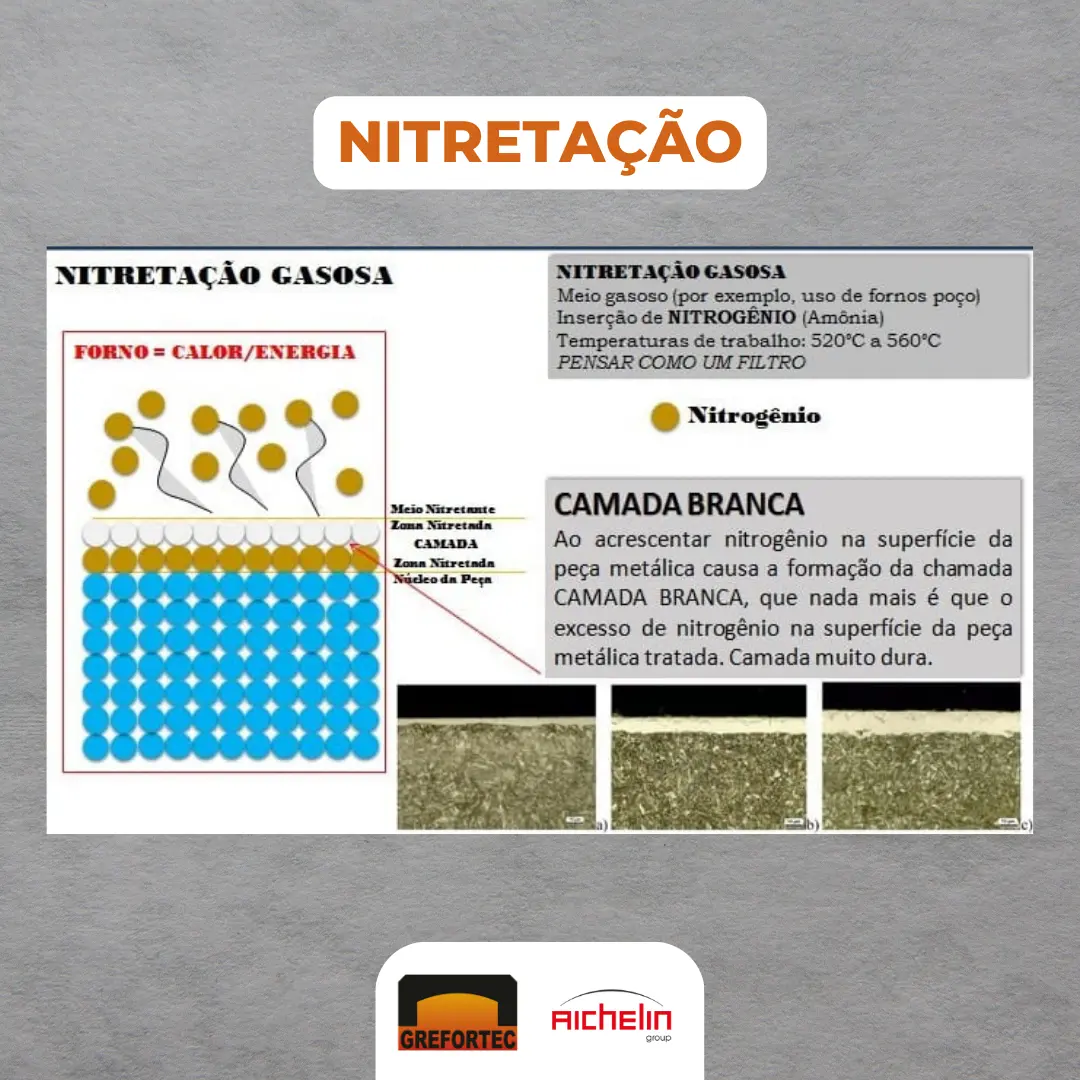

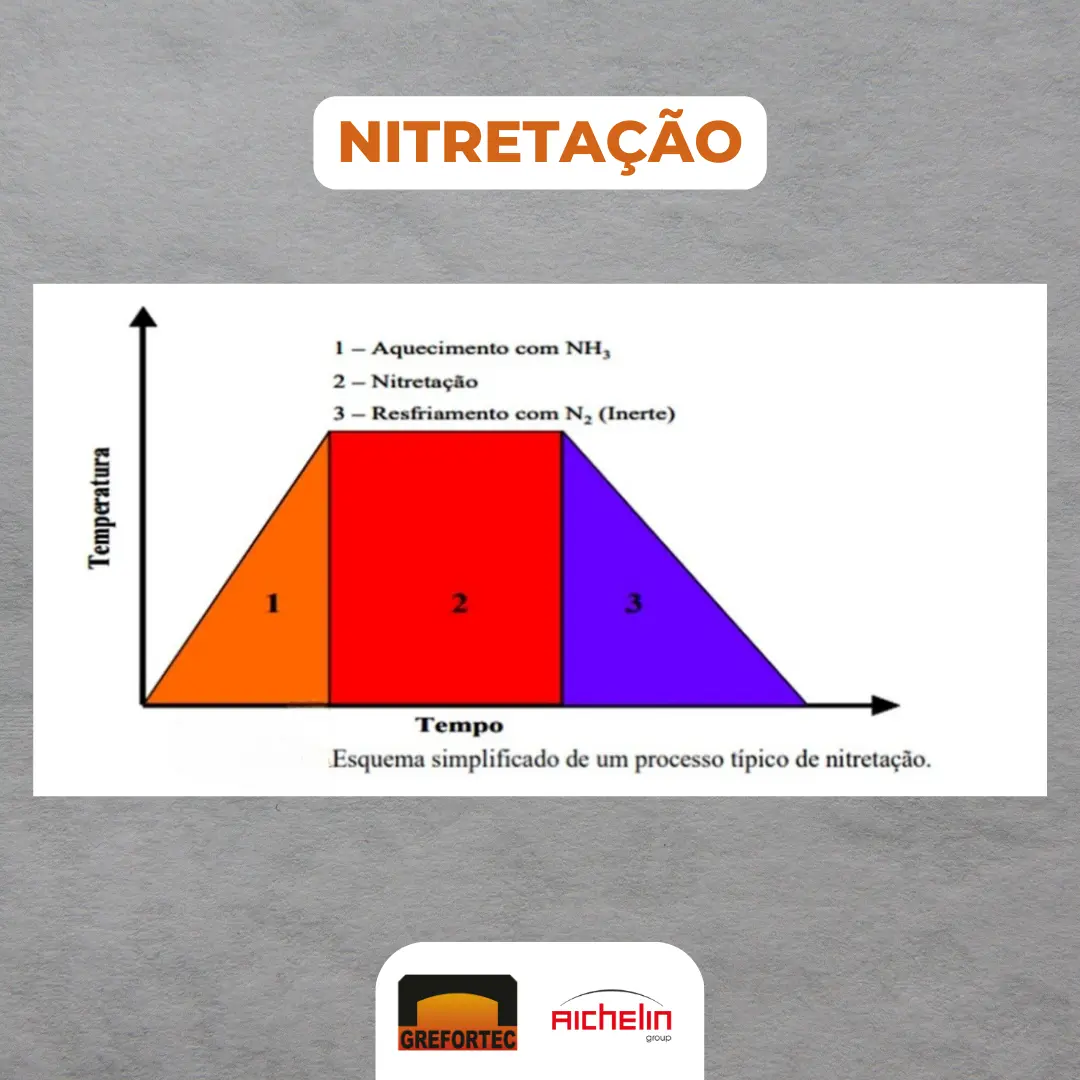

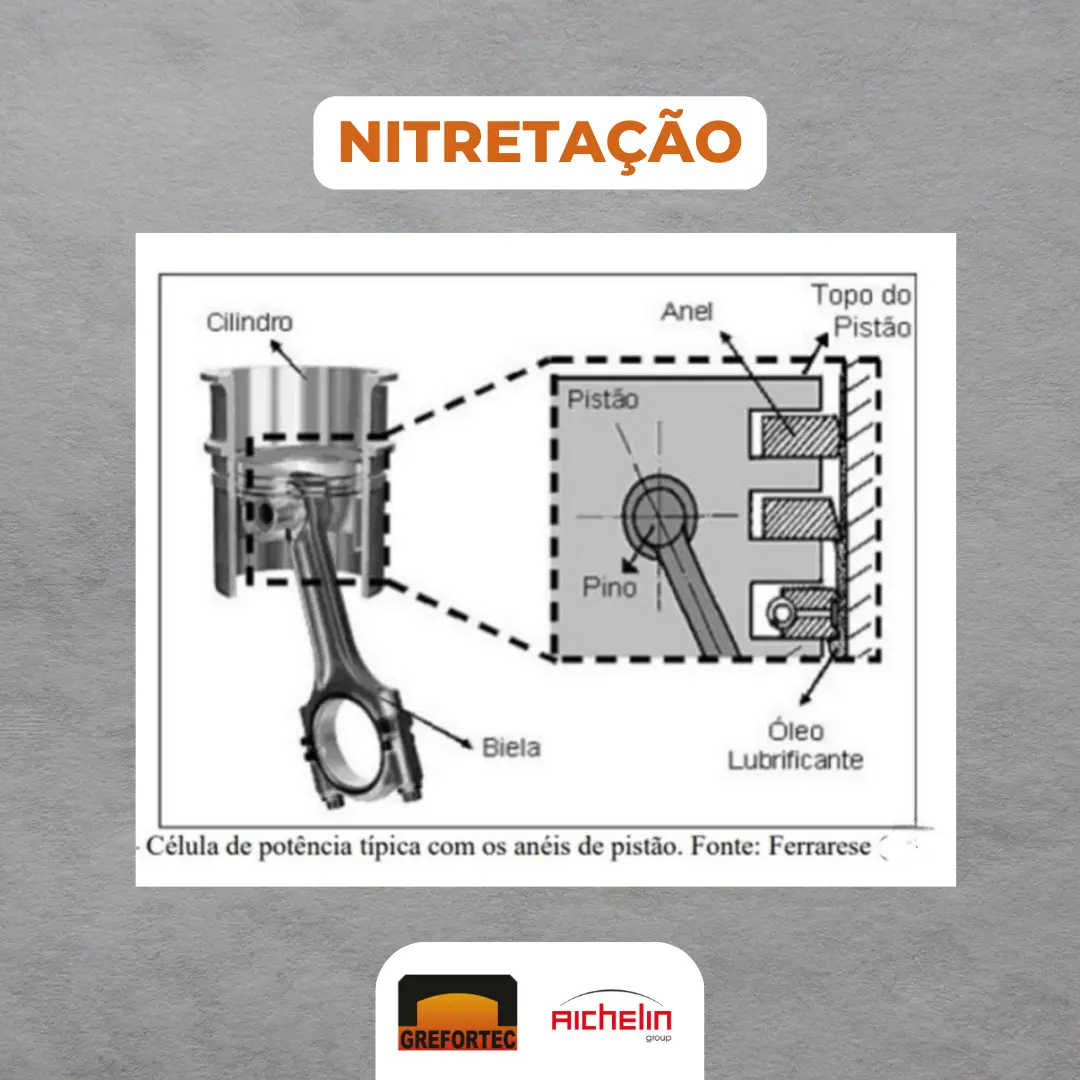

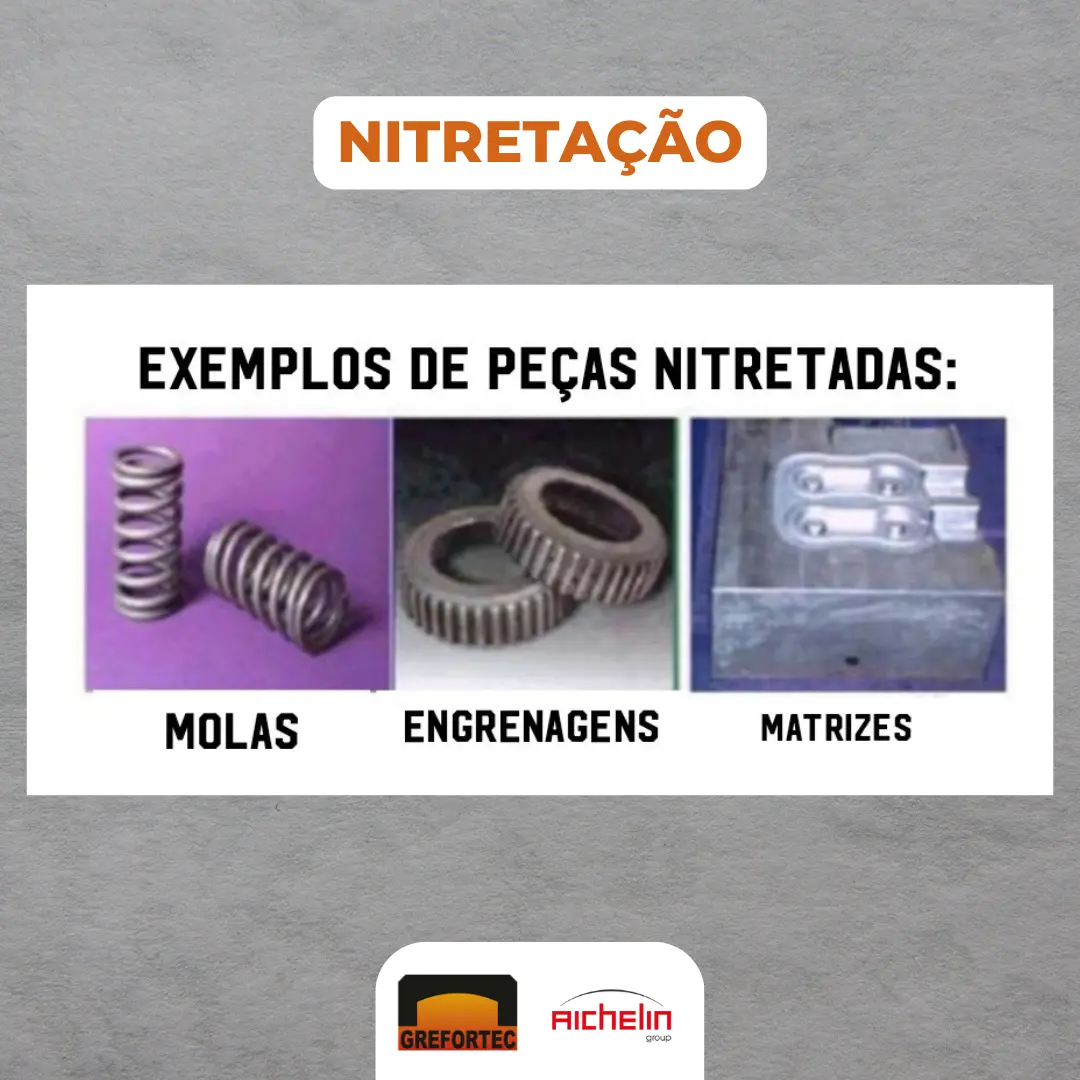

This process consists of introducing nitrogen onto the steel surface, by heating it between 500 and 570°C, in order to obtain a hard layer of nitrides.

Because it uses lower temperatures than carburizing, the nitriding produces less distortion and less tendency to cause cracks in the material.

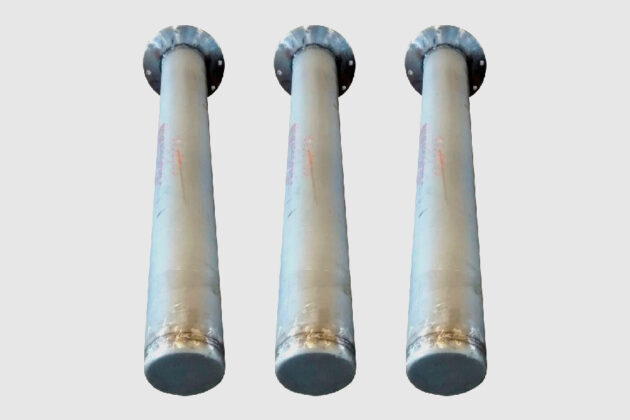

Grefortec also manufactures ovens furnaces for Nitriding, such as:

Grefortec Maintenance

Benefits

We have a qualified team to handle corrective and preventive maintenance on industrial equipment from our brand and also from other manufacturers. Our professionals are trained and qualified in accordance with the Safety Regulations. We go to your company to carry out maintenance on site.

Of production time is wasted due to lack of maintenance

Of industrial companies use preventive maintenance

It is the Grefortec maintenance satisfaction index

Renovations and Retrofit

Team specialized in general renovations, recovering everything from the structure and plating to the electronic parts. Grefortec also has Know-how for retrofit services, refractory and insulation reforms.

Availability

Our technical team is available for you with the possibility of carrying out maintenance in loco, without the need to travel. We come to your company!

Spare Parts

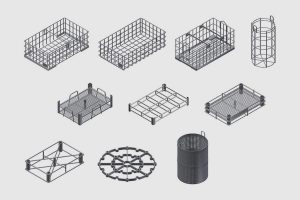

Resistors, radiant tubes, conveyor chains, atmosphere recirculators, baskets, grids and miscellaneous items:

Resistance

Radiant Tubes

Conveyor-currents

Atmosphere Circulators

Baskets and Grilles