CONTINUOUS WASHERS

Grefortec continuous washers can be used to carry out automatic cleaning in the most varied types of industrial processes, including heat treatment. One of the advantages of this model is the conveyor belt handling system, in which the part enters with dirt on one side of the washer and comes out fully sanitized on the other side.

The constructive concept of a Grefortec continuous washing machine is determined through a critical analysis of the end customer's process. The project is customized based on the customer's production information, degree of soiling, available layout, processes before and after washing.

This model can be used in several application processes, such as: post-hardening, post-machining, large parts and maintenance.

Construction Features:

- Built on geometry consecrated by efficiency, with application of intuitive design in the areas of connectivity and interaction;

- Washing system designed according to the severity and degree of dirtiness;

- Frame and structure built in appropriate materials for the severity of the application, guaranteeing robustness and longevity to the equipment;

- System of independent tanks, with built-in heating and filtering;

- For baths with electric heating, it has power control by electronic means of high reliability, via solid state or thyristor modules;

- For baths with gas heating, the control systems have approved programmers and safety systems according to NBR 12313;

- Micro processed temperature control system, work and safety pyrometry, for systems with forced drying;

- Systems for automatic application of anticorrosive treatment (optional) such as painting, protective oil and coating;

- It contemplates the Brazilian Occupational Health and Safety Standards with: NR 10, NR 12, NR 17, Preliminary Risk Analysis report, certification reports and effectiveness ART.

Grefortec Maintenance

Benefits

We have a qualified team to handle corrective and preventive maintenance on industrial equipment from our brand and also from other manufacturers. Our professionals are trained and qualified in accordance with the Safety Regulations. We go to your company to carry out maintenance on site.

Of production time is wasted due to lack of maintenance

Of industrial companies use preventive maintenance

It is the Grefortec maintenance satisfaction index

Renovations and Retrofit

Team specialized in general renovations, recovering everything from the structure and plating to the electronic parts. Grefortec also has Know-how for retrofit services, refractory and insulation reforms.

Availability

Our technical team is available for you with the possibility of carrying out maintenance in loco, without the need to travel. We come to your company!

Spare Parts

Resistors, radiant tubes, conveyor chains, atmosphere recirculators, baskets, grids and miscellaneous items:

Resistance

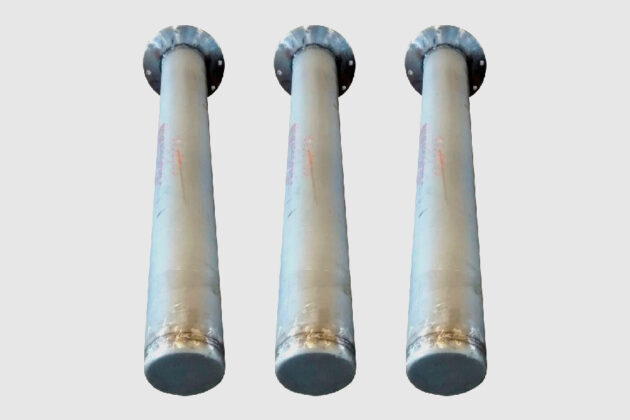

Radiant Tubes

Conveyor-currents

Atmosphere Circulators

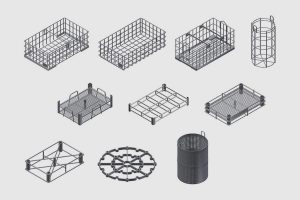

Baskets and Grilles