Annealing

This kind of Heat Treatment is carried out to achieve one or more of the following targets:

- Remove stresses due to cold or hot mechanical forming;

- Decrease the hardness to improve the machinability of steels;

- Changing mechanical properties such as resistance, ductility or others;

- Modify electrical and magnetic characteristics;

- Adjust the grain size;

- Regularize the raw melting texture;

- Remove gases;

- Produce a defined microstructure;

- Eliminate the effects of any Thermal or Mechanical Treatment to which the steel has been submitted.

Os processos de recozimento subdividem-se ainda em: processo de recozimento total ou pleno, recozimento isotérmico ou cíclico, coalescimento ou ainda recozimento para alívio de tensões. Veja abaixo uma explicação detalhada sobre cada processo.

-> Total or full annealing: consiste em aquecer o aço acima da zona crítica de temperatura, durante o tempo necessário e suficiente para se ter solubilização do carbono ou dos elementos de liga no ferro gama, seguido de um resfriamento muito lento, seja mediante o controle da velocidade de resfriamento do forno ou desligando-se o mesmo e deixando que o aço resfrie dentro do forno. Nestas condições obtém-se perlita grosseira que é a estrutura ideal para melhorar a usinabilidade dos aços de baixo e médio carbono.

-> Isothermal or Critical Annealing:consists of heating the steel under the same conditions as the total annealing, followed by a rapid cooling to a temperature located within the upper portion of the isothermal transformation diagram, where the material is kept for the time necessary to produce the complete transformation. Then, cooling to the room temperature can be faster and the resulting final structure is more uniform than in the case of total annealing.

> Coalescing or Spheroidizing: it is an annealing process that aims to obtain a globular or spheroidal shape of carbides in steel and with very low hardness for use in parts that request plastic deformation. Generally, the parts are kept at a temperature slightly above the lower transformation line, followed by slow cooling or heating for a long time at a temperature just below the lower line of the critical zone, or alternating the two possibilities mentioned above.

-> Anneling for Stress Relief: It consists of heating steel to temperatures much below the lower limit of the critical zone, and the objective is to relieve stresses originated during solidification or produced in cold mechanical transformation operations, such as deep stamping, or even in straightening, flame cutting, welding or machining operations.

Grefortec also manufactures furnaces for Annealing, such as:

Grefortec Maintenance

Benefits

We have a qualified team to handle corrective and preventive maintenance on industrial equipment from our brand and also from other manufacturers. Our professionals are trained and qualified in accordance with the Safety Regulations. We go to your company to carry out maintenance on site.

Of production time is wasted due to lack of maintenance

Of industrial companies use preventive maintenance

It is the Grefortec maintenance satisfaction index

Renovations and Retrofit

Team specialized in general renovations, recovering everything from the structure and plating to the electronic parts. Grefortec also has Know-how for retrofit services, refractory and insulation reforms.

Availability

Our technical team is available for you with the possibility of carrying out maintenance in loco, without the need to travel. We come to your company!

Spare Parts

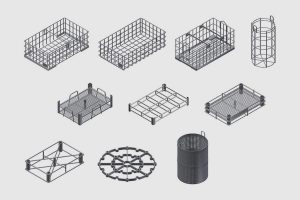

Resistors, radiant tubes, conveyor chains, atmosphere recirculators, baskets, grids and miscellaneous items:

Resistance

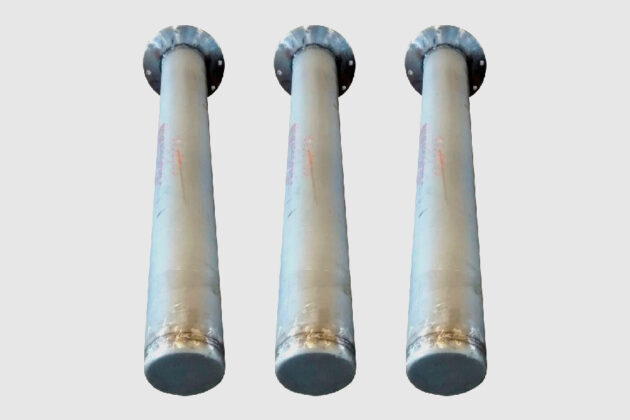

Radiant Tubes

Conveyor-currents

Atmosphere Circulators

Baskets and Grilles